Refit ~ Phase II

If you ask any cruiser, when you own and live on a boat there is always a project list. Often, you can pick and choose to do your maintenance and upkeep projects in-between snorkeling, beach walks and socializing. Sometimes you have to make an emergency repair in paradise! Other times you dedicate a block of time and go deep into “project mode”, which is where we are living now.

Following the electronics and electrics projects of last year, we have now entered into the optimization and beautification phase of our refit. The last phase will be rigging and sail plan to finish out the year. All of this does mean sacrificing a cruising season this winter, but it will be well worth it for us when we take off again on our new and improved home.

Our new boat will be officially transformed and hold up to its namesake Reach by the time we’re through!

Running gear

When delivering the boat from Antigua to Georgia last year, we noticed plenty of friction in the older lines and gear itself. In fact, we had to purchase a main halyard immediately at our first stop in St Thomas in order to appropriately use the main sail.

The rest of the running rigging has since been replaced. Now the task is to re-run the lines to the helm, in a nod to the Manta Catamaran. This will enable all of the sail controls to be accessed at the helm, with the exception of the split mainsheet at the stern. So far, we have been pleasantly surprised with this set-up in the ease of mainsheet control (in lieu of a traveler) for mainsail shape and jibe control.

Add clutch and block to carbon bowsprit (galvanically isolated) at screecher for ease of changing out with spinnaker

Serviced and cleaned mainsheet winches x2

Replaced main halyard mast block

Installed reefing blocks on boom

Installed 2 new rope clutches for jib sheets run to main winch

Installing deck organizer and multi-rope clutch to run reefing lines and main halyard to main winch

Fixes

There have been a few tests and/or repairs needed that percolated up to the top of the list over the last couple of months.

We find many parts have unique Brazilian origins that are hard to tie into (e.g, sink drain) without a complete rebuild or kludge with locally sourced parts.

These projects are routinely interspersed with plenty of creative cussing.

Replace generator fuel hose ~ tracing small but annoying diesel leak(s)

Test the new SSB using the shroud as an antenna ~ chat with friends in the Bahamas

Troubleshoot issues with the new Simard autopilot head kicking out of NAV mode (intermittent issue on our recent passage)

Replace generator injector fittings, o-rings and hoses ~ still tracing small but annoying leak(s)

Relocate air compressor in starboard locker to make room for new watermaker

Fix sliding door so it wouldn’t slide in a wake or seaway (or fall off altogether!)

Fix port holding tank, resealing lid and install new vent

Tighten generator fuel system fittings not yet examined ~ in effort to stop that &^#@%$! small but annoying leak(s)

Replumb galley sink to eliminate small leak

Upgrades

Watermaker:

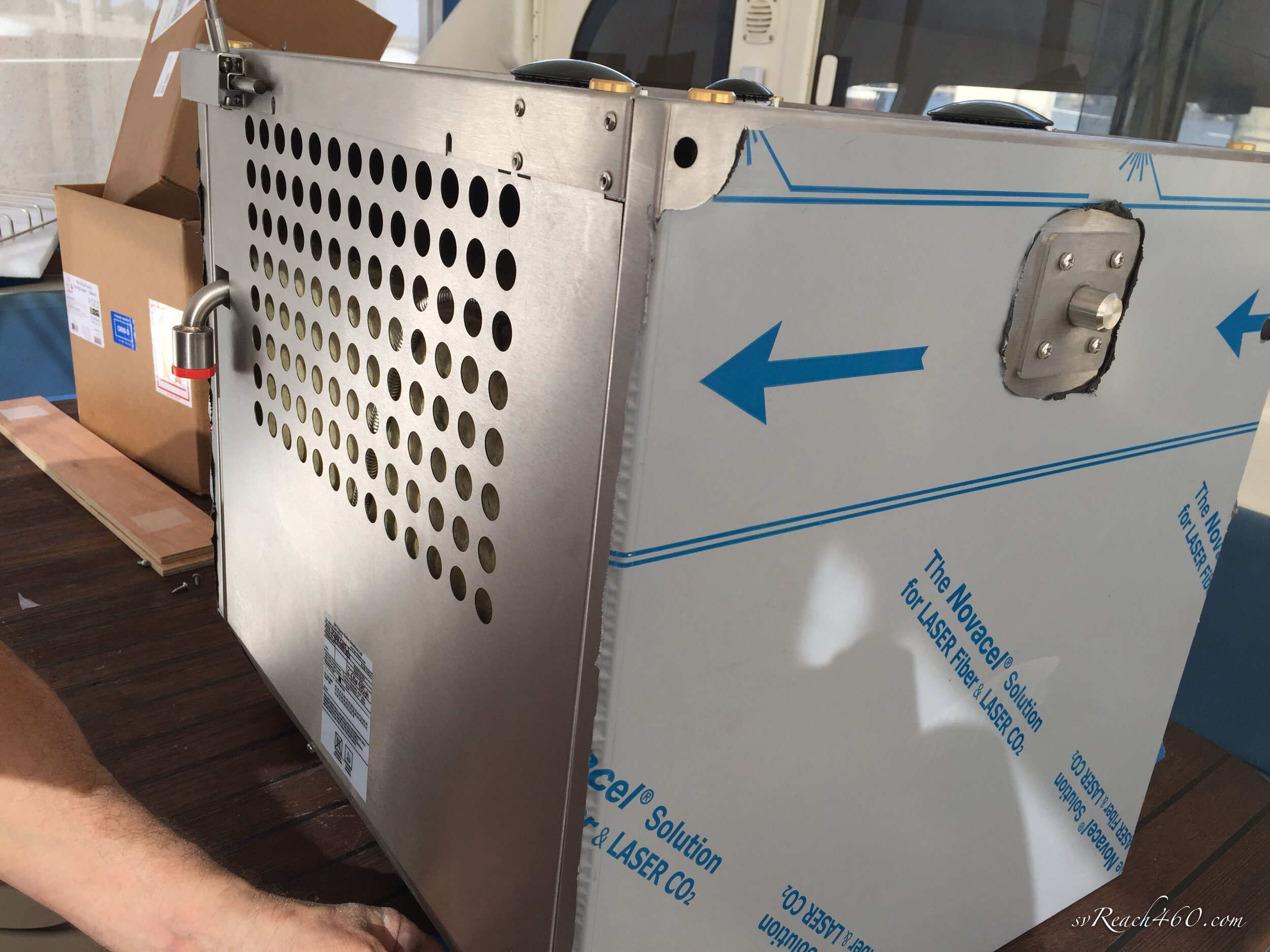

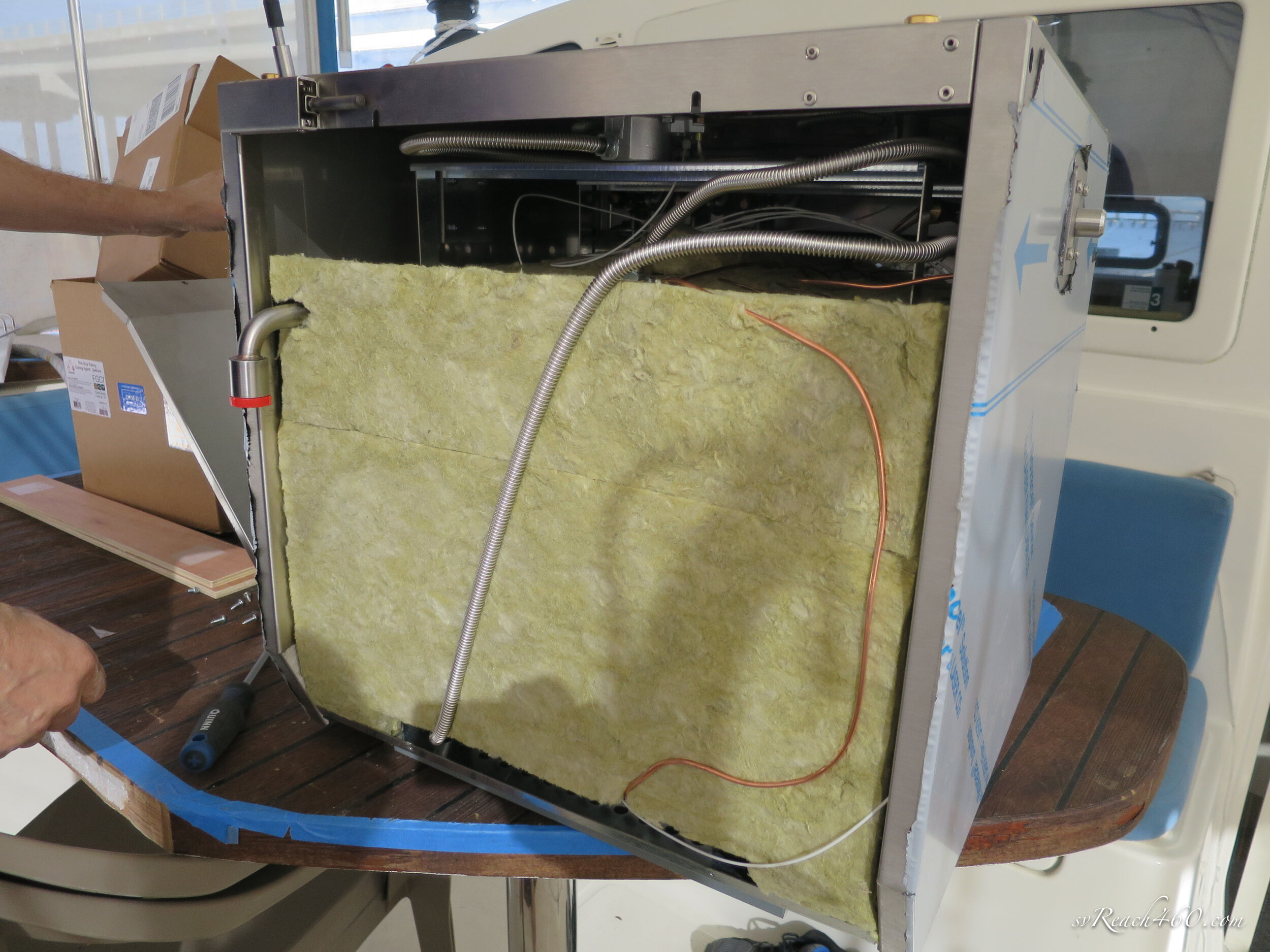

We had always planned to upgrade to the Cruise RO watermaker that we’d used previously. We sold the existing Specta watermarker (8 gal/hr) with its z-brain to another couple outfitting their boat for extended cruising.

Once going to 30 gallons per hour water production, it was a game changer in the way we used and made water. No more worrying about water or power, while still using each in reasonable boating-mode, neither would ever become an issue or stressor. Even though AC-powered, the solar and Lithium battery bank allows us to make water without needing the generator.

Since the Cruise RO system is modular, we found a great place in the bow locker to mount the dual membrane system and related filters and pumps. Once tested, it is now pickled for our marina stay.

Propane stovetop/oven:

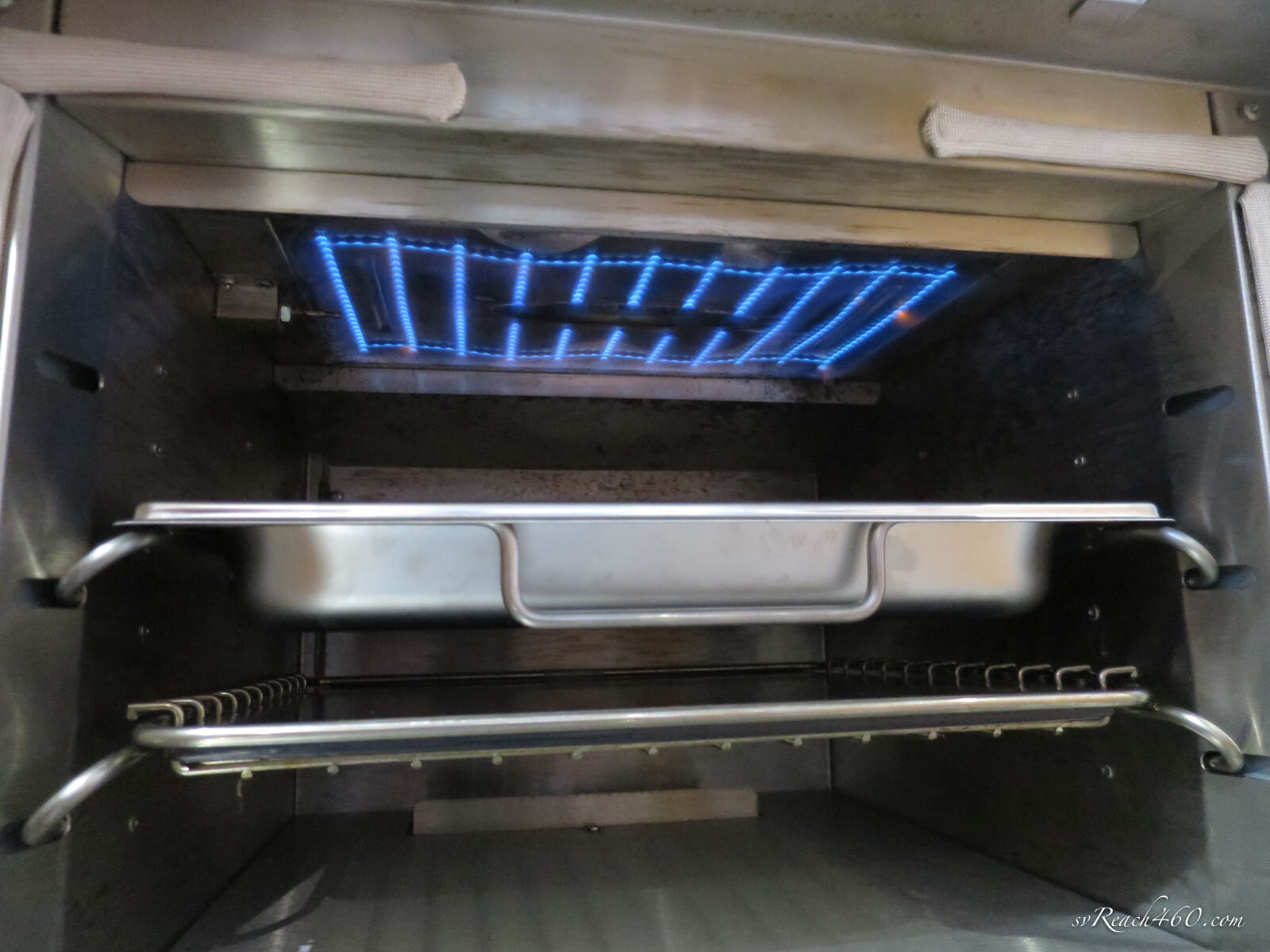

An unplanned upgrade was replacing the SMEV propane stovetop oven with a GN Espace stovetop and oven. The former had rusted out burners and the oven barely reached a usable temperature. After several baking disasters, we noted that we needed to bake for at least twice as long as a normal recipe.

The new oven is pretty amazing. It has three rack heights with gastronorm 2/3 sized cookware and an awesome broiler/grill that creates a “blanket” flame on the top of the oven. The stovetop has three burners and extremely precise control with very useful simmer control. It also has a fancy gimble that we didn’t need to use and uninstalled. Overall, a great find!

Electronic throttles:

Since day one, we have had a very sticky port shifter that takes two hands to put into gear and neutral. It isn’t uncommon to do a harmful hard shift into the opposite gear unintentionally. It had a long mechanical cable run that was worked and reworked, while the shift at the engine itself remains as smooth as butter.

Add to that, the throttles are in an awkward position at the helm under the main winch, about hip height at about a 45 degree angle… AND this is where all of our new lines will be falling as we run three additional lines to the main winch… so we started to rethink throttle location. Once we started thinking about re-running shifter cables in various locations, it was a slippery slope to just take mechanical cables out of the equation altogether!

So we decided to go for it and purchased a Uflex Electronic shift and throttle system. It will now fit in a much smaller footprint right over the wheel. Mark laid-up a small fiberglass mount (using a galley tupperware!) that fit in the space just right.

The power distribution unit runs power to a CAN bus for power and communication distribution to the bus, as well as to the actuators, for localized shift control and throttle control at each engine.

Beautification

The following projects are in-progress with contractors here in Brandenton/St Pete that have been under design and are about to become reality. This is one area where we are happy to rely on the professionals for top-notch fit-and-finish work. These will make our living space much more comfortable and our home complete.

The next month or two will be VERY exciting and these projects will get their own blog updates when complete… but I’ll share a few sneak peeks for now.

Cockpit:

Build aluminum pilot structure at the helm for improved functionality and visibility

Design and build new cockpit enclosure to enable full weather protection

Add cockpit shades for sun protection

Replace and cover all cockpit cushions

Settee:

Design and build new u-shaped settee in saloon from fiberglass mold

Cut out oval settee

Install new fiberglass settee into saloon

Replace raised floor under settee

Build new table for settee

Other:

Design and install custom forward opening hatches for saloon

Reinforce dinghy davits

Polish & have name put onto the hulls… s/v REACH